Over the summer, I began adding more miners. The weather had started to warm up about the same time so the Furys started to increase in temperature. In our area most places do not have air conditioning, so we are up to the mercy of the weather. Most of the year it’s a cooler climate off the central coast of California, but this year it has been much warmer. Even without the weather, the Furys ICs would get hot but not the casing, which is a giant heat sink anyway. That told me there is poor thermal transfer. I had to do something about it. Cooler ICs means less hardware errors which means more accepted shares.

Upon research I narrowed down to these two items:

- Prolimatech PK-3 Nano Thermal Paste (comes with spatula) – Amazon

- ArctiClean Thermal Paste Cleaner – Amazon

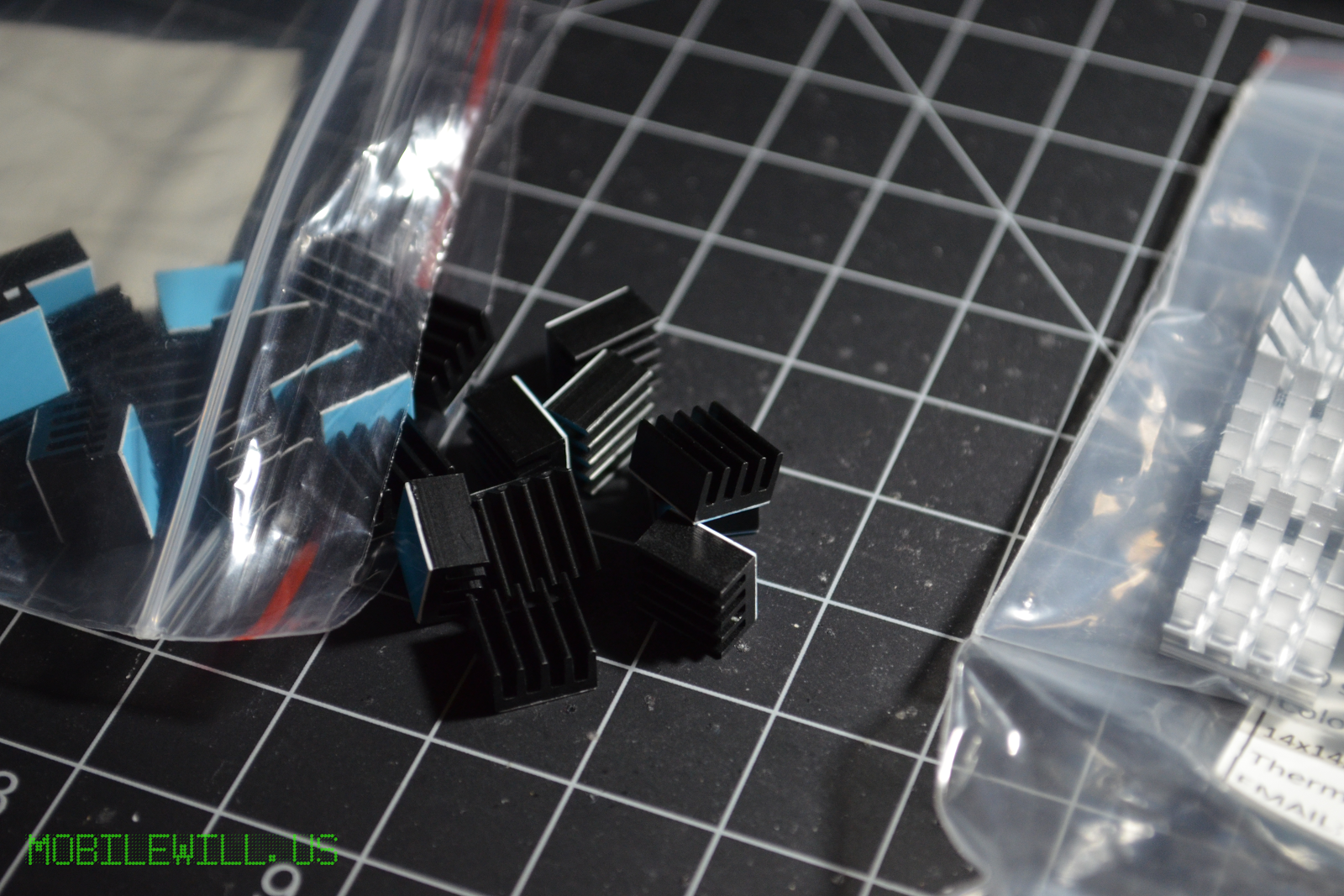

- .6in Heatsinks – AliExpress (My first purchase from AliExpress)

- Came with extra Raspberry Pi heatsink sets

Wait, err, make that three items – the cleaner was one of those things on Amazon “people also bought.” The stuff works great but I ended up only using it on the first one so I could conserve paste.

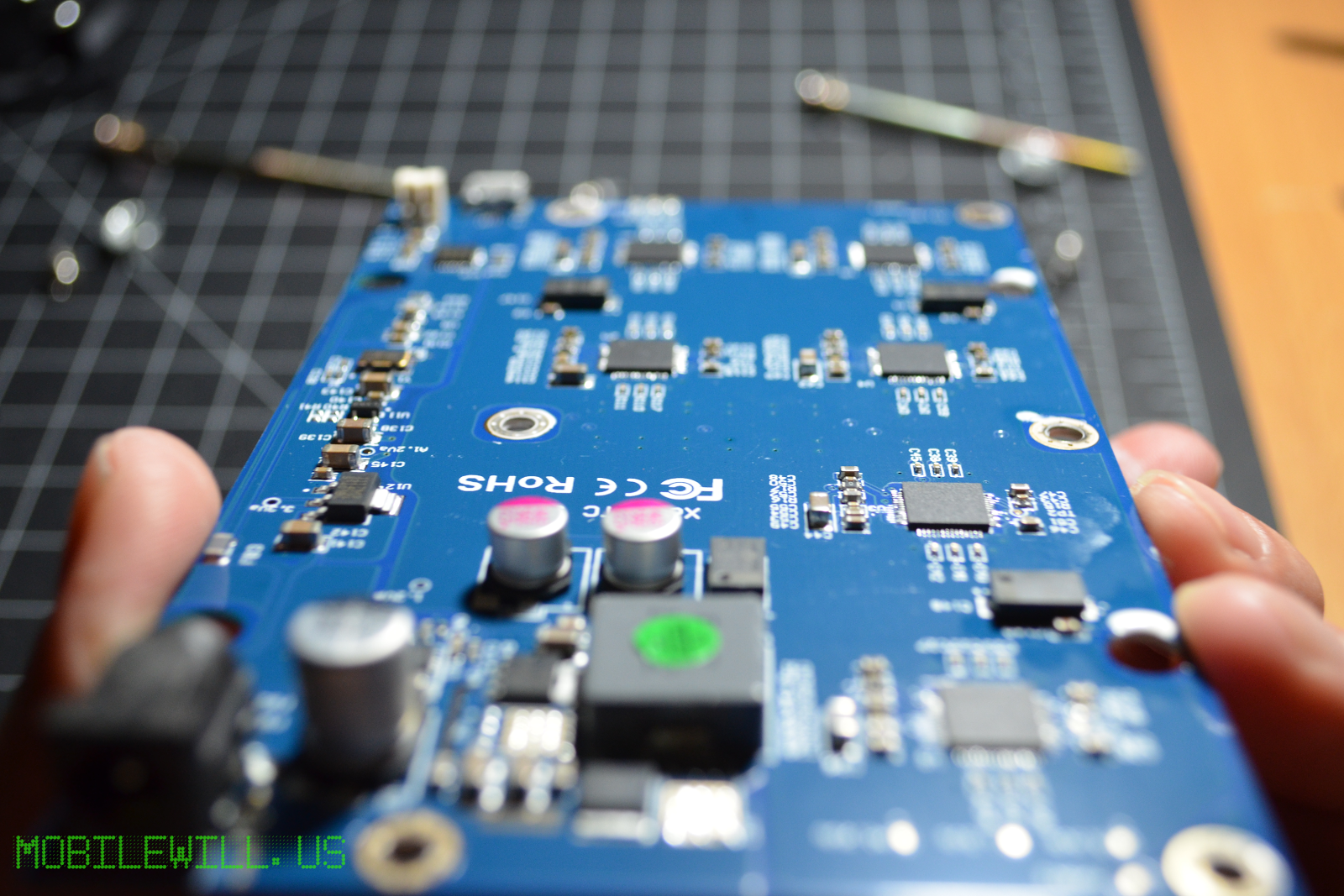

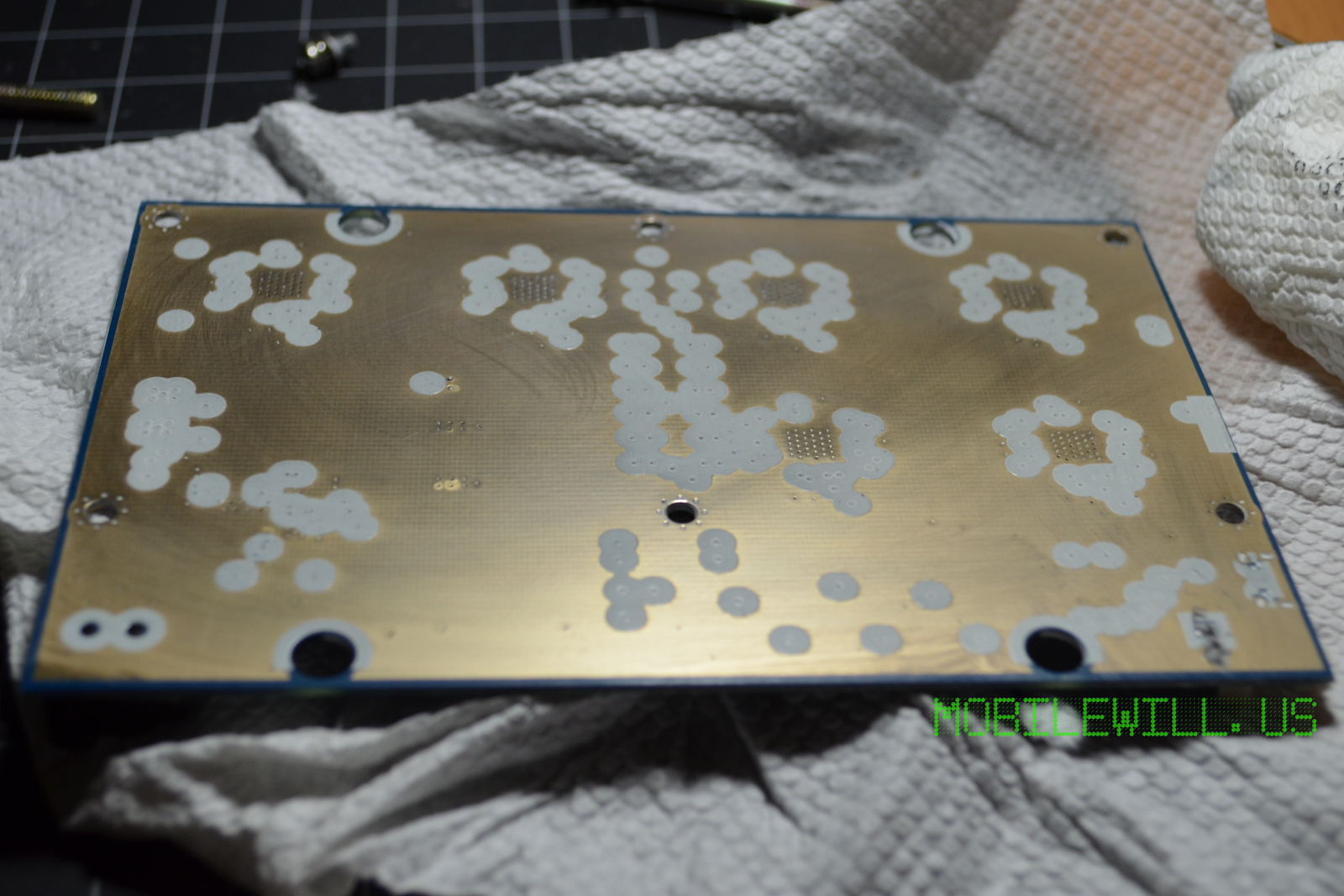

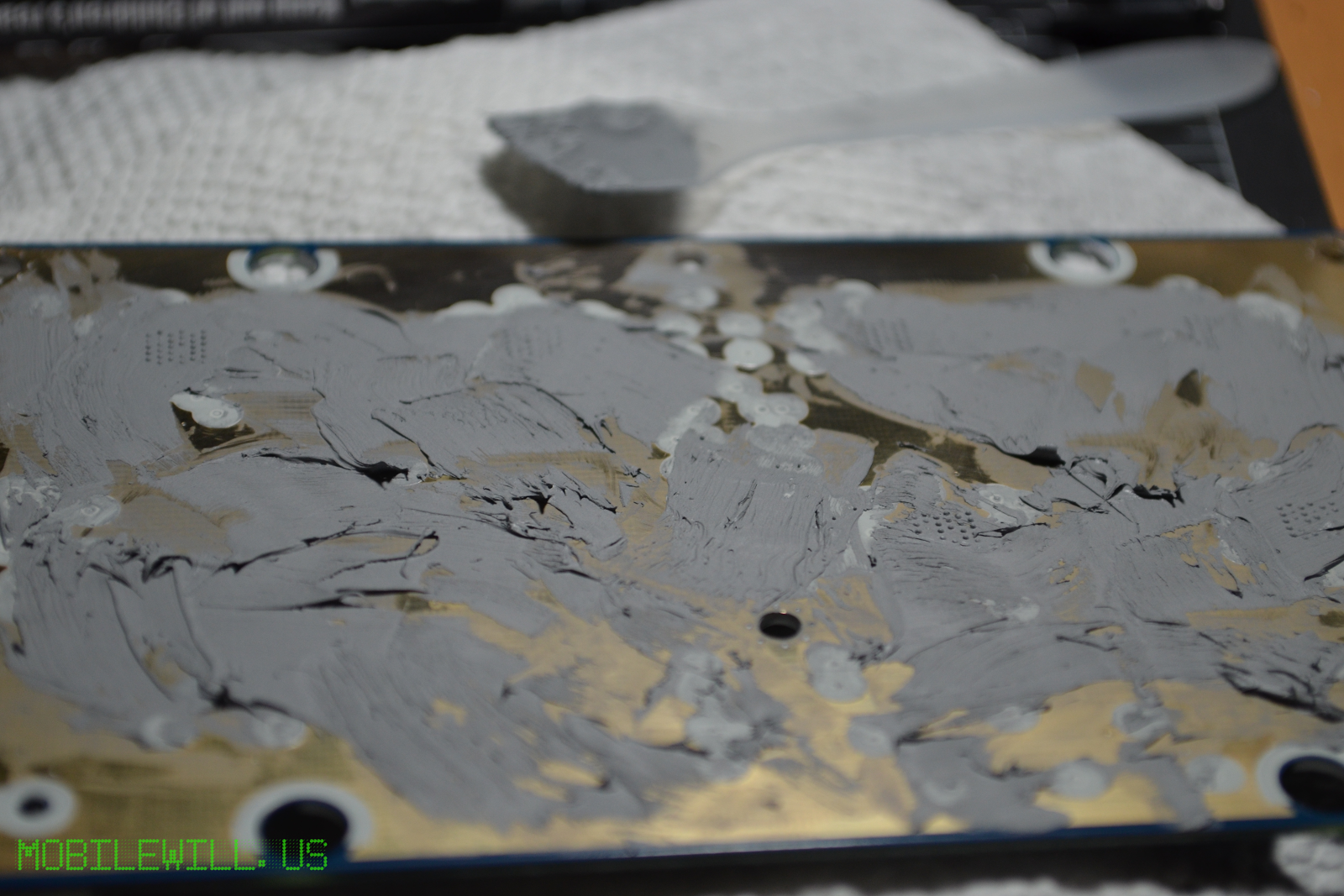

Some people only put paste on the backside of the ICs and not the entire PCB which I don’t understand. The entire PCB is used to transfer heat so why not try and transfer as much as possible to the casing? In reality, using the PCB to transfer heat from one side to other isn’t the best design but I can see why they did it. From what I have heard somehow the ICs are designed to work this way. If you look closely there are small vias underneath the IC to transfer heat.

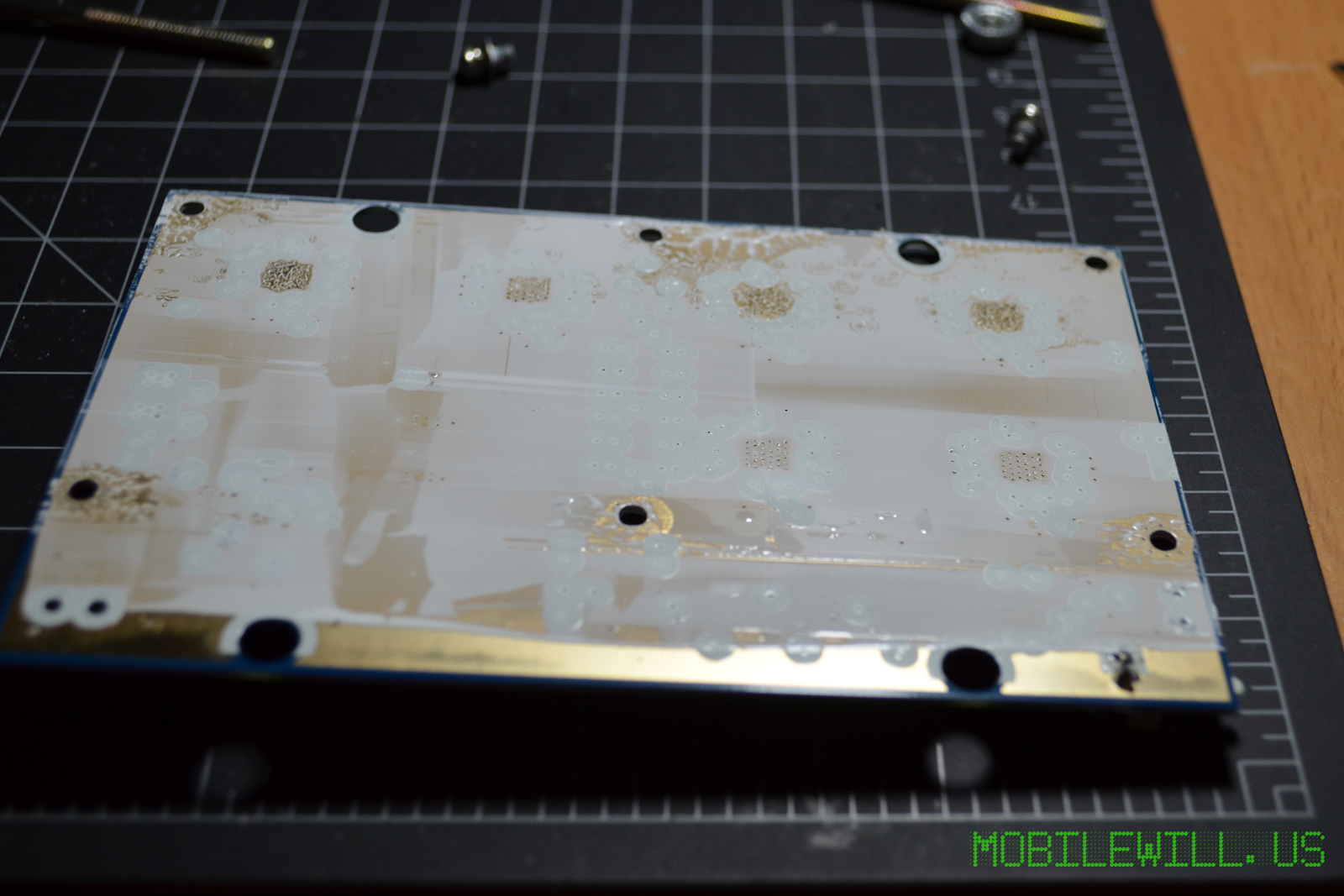

On the first Fury I used the paste cleaner to clean off all of the paste. Wow! That stuff is amazing! I wish I had that back in my PC repair days! First you use the cleaner to get rid of the paste. Then the purifier to prep the surface to apply fresh paste. On the rest of the Furys I just wiped the paste from the back of the ICs and applied the new paste. I left the original paste to cover the rest. Maybe not the ideal solution, but I didn’t want to have to buy more paste.

Just squirt a drop of paste on each IC and spread it around with the spatula. This is one of those few cases where less is more. If you have too much paste you won’t get good heat transfer. I found that out the hard way years ago with a CPU heat-sink.

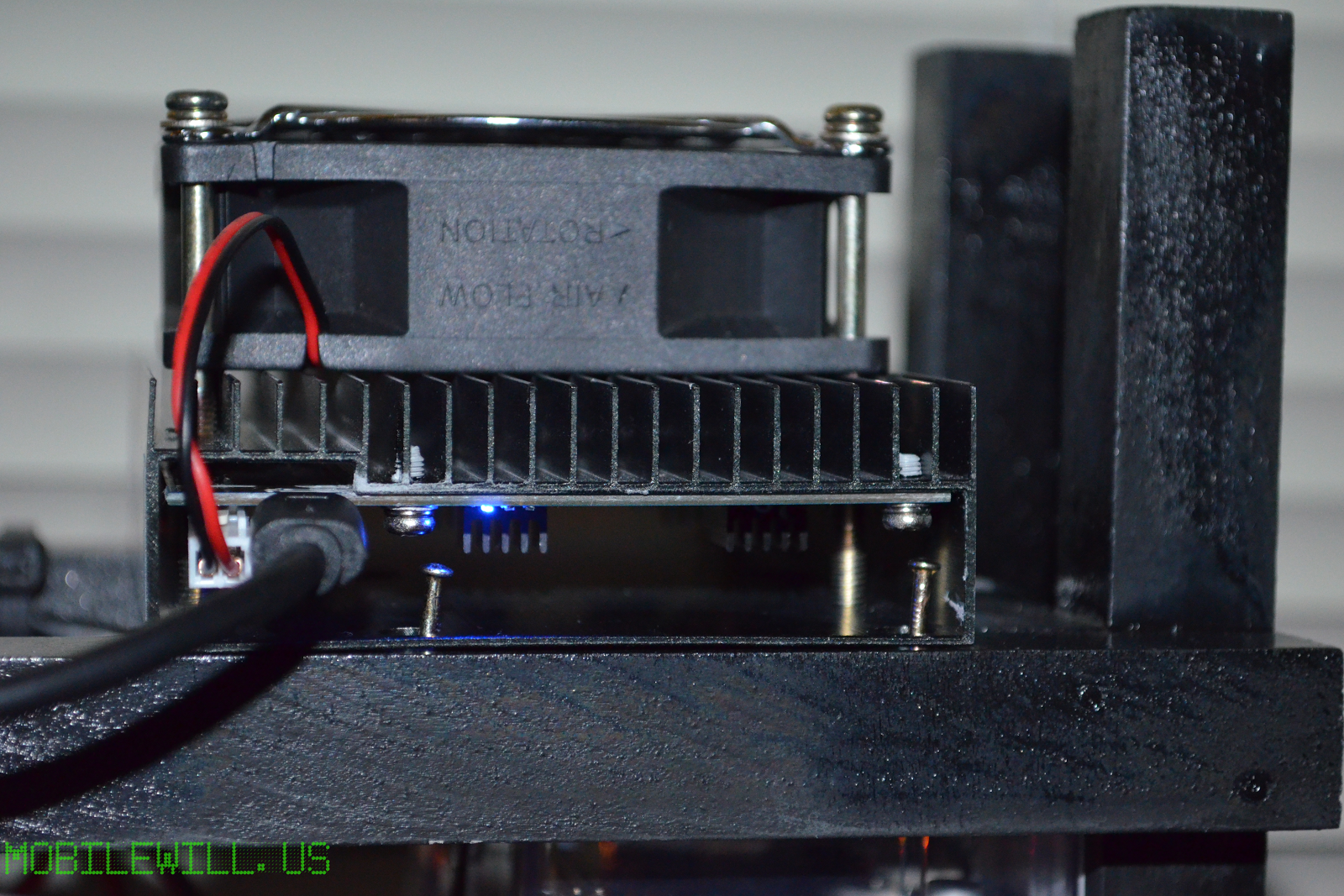

The heat-sinks come with 3M thermal tape. Using tape might not be the best but I figured its from 3M and anything is better than no heat-sink. I stuck them on parallel with the casing. That way the air flows through the center and through the fins of the heat-sink. If you have enough you could put heat-sinks on the regulators. I only did on one since I didn’t have enough because I purched a few more Furys than when I ordered the heat-sinks. Not sure if it really is needed. It might help for longevity, but I am sure the profitability will drop before they die. Especially with California power prices which are increasing as I type.